A customer visit to Emperor Mouldings B.V. in Alphen aan den Rijn, the Netherlands.

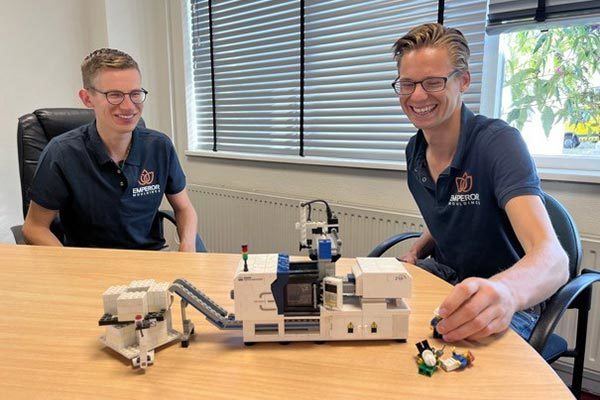

Brothers Maarten and Peter Keijzer, heads of Emperor Mouldings B.V., embody a new generation of injection molders: focused, efficient and relaxed – with a new understanding of work-life balance. In the Zhafir Zeres Series, they see the best prerequisites for making injection molding processes as efficient as possible and driving production automation forward.

Growing up in his parents‘ injection molding business, Maarten Keijzer knew very early on that he wanted to run an injection molding company. The fact that his father then sold the business turned out to be a good decision in retrospect, as Maarten quite inevitably had to found and build up his own company. He took this step in 2019, initially alone, but since 2022 his brother Peter has been completely on board.

Both had precise ideas from the start: „No employees for as long as possible, but to bring production to the maximum, so far that we can still manage everything with just the two of us.“ The main products are clips of agricultural use; the end customers are greenhouse operators. In addition to the agricultural industry, they still supply the commodity sector and technical parts. The bottom line is that they focus exclusively on small shot weights in high volumes. This is because highly efficient processes, „production-friendly“ products and automation in places where it is worthwhile and serves the work-life balance are important to them. Maarten Keijzer: „I certainly experienced many things in my father’s company that I wanted to do differently. The principle ‚Only those who work hard will make it‘ may have had its justification in those days. Today, we have other options. In the age of digitalization and its tools, it’s easier to design efficient and lean processes.“ The recently introduced automated foiling of cartons is a good example of this, he said. „This robot saves us a lot of valuable time.“ They are currently considering an AGV, which would then take the full cartons out of the magazines at night, increasing piece counts.

Ständige Verbesserung der Prozesse: Mark Waterreus (Inhaber von Robotech, HTIG-Vertriebshändler in den Niederlanden) im Gespräch mit den Brüdern Keijzer.

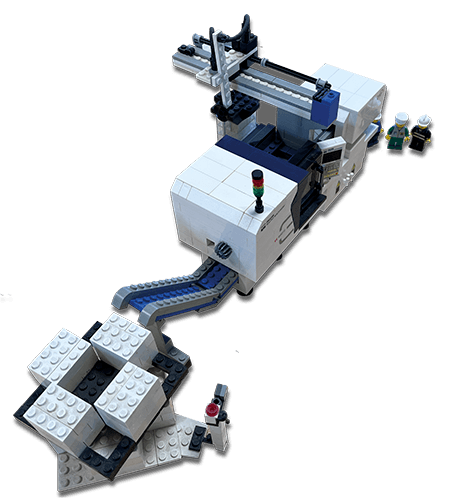

Leidenschaft für Technik: Maarten (links) und Peter Keijzer mit einem Venus-Modell aus Lego, das sie mit Robotertechnik und Peripheriegeräten ausgestattet haben.

Über sinnvolles Wachstum und Skalierbarkeit

Seit der Gründung im Jahr 2019 ist Emperor Mouldings B.V. in Bezug auf Produktion, Umsatz und Einrichtung stetig gewachsen. „Wenn die Nachfrage da ist, macht es keinen Sinn, nicht zu wachsen“, sind sich die Keijzers einig. „Aber immer mit Maß und Ziel.“ Dennoch sei das Wachstum im Allgemeinen nicht das große Ziel, sondern die „sportliche Herausforderung“, mit den vorhandenen Maschinen und ihrer 2-Mann-Kraft möglichst viele Produkte zu versprühen. „In unserer Produktion gibt es Platz für acht Maschinen. Das ist immer noch eine Größe, die wir mit zwei Leuten bewältigen können. Und sollte der Markt mehr verlangen, werden wir sehen, wie weit wir mit unserer Arbeitskraft gehen können.“

Wachstum in diesem Sinne setzt voraus, dass die Prozesse auf maximale Effizienz hin optimiert werden. Dass die Zykluszeiten maximal verkürzt werden und der 24/6-Nonstop-Betrieb maximal reibungslos läuft, mit einer klar fokussierten Produktgruppe: einfache Kleinteile in großen Mengen.

Dementsprechend haben sie ihren Maschinenpark ausgerichtet und um eine hohe Genauigkeit ergänzt. Das Herzstück der Produktion bilden derzeit fünf elektrische Zeres-Maschinen mit viermal 900 und einmal 1.200 kN Schließkraft (eine weitere ist in Auftrag). Alle laufen mit integrierten Steuerungen (Success Series 7 und 11) von Sepro Robotics. Die Werkzeuge sind mit externen Heißkanalsystemen von PSG ausgestattet, und eine speziell programmierte Fehlerabschaltung greift ein, wenn die Temperatur im Dosiergerät zu hoch ist. Dies garantiert ihnen auch eine nahezu fehlerfreie Produktion bei Emperor Mouldings. Originalzitat Maarten Keijzer: „Wir hatten bisher nur 1 Karton Ausschuss im Jahr 2022.“

„Der elektrische Zeres passt sehr gut zu unserer Philosophie: Technik auf den Punkt für die Produktion auf den Punkt. Auch das Preis-Leistungs-Verhältnis ist in unseren Augen unschlagbar. Unser erster 90-Tonner Zeres hat bereits mehr als 6 Millionen Zyklen ohne nennenswerte Störung absolviert.“ Maarten Keijzer, Emperor Mouldings B.V.

Performance against rising energy costs

While the young company has come through the pandemic relatively well and relaxed, the energy crisis is having an even more serious impact on its core market, the Dutch agricultural industry. Rising energy prices are likely to bring many greenhouse owners to their knees, by next winter at the latest. „Our warehouse is full and the market is saturated for now. That means that of our machines, only two out of five are currently running. The reason for this is that the agricultural industry is suffering extremely from rising energy prices and many end customers have already announced that they are closing their greenhouses for the winter.“ The two brothers nevertheless take the situation calmly: „A crisis is also always an opportunity. Up to now we’ve had full capacity utilization, now we’re using the quiet phase for new customer acquisition, internal projects that have fallen behind, or we’re happy to have more family time.“

Of course, rising energy costs are also making themselves felt in their own injection molding operations, but their stringent decision to use electric machines and the low shot weight of the small parts keep their energy consumption within limits. In any case, they optimize their injection molding processes for maximum energy savings to keep their carbon footprint as small as possible.

First certified industrial compostable clipring made of PLA’

Apart from that, they keep on working on continuous automation of production, keyword: increasing efficiency. „The electric machines are a tremendous help for us to produce in this high efficiency. Our father had hydraulic machines, he still had to ramp them up with some lead time and wait until the oil temperature was right, sort out some cycles of scrap and so on. We turn our Zeres family on Monday morning and don’t turn them off until Saturday night. Machines and the Success line from Sepro are an ideal match. From the first shot, production is error-free,“ explains Maarten Keijzer.

In his opinion, another important building block for higher efficiency is material-optimized processes, in which he gained valuable experience in his previous job at a material supplier. „Our injection units are all equipped with a shut-off nozzle, so we can maximize parallel functions during energy-intensive plasticizing. Every second saved has an immediate impact on energy costs.“

In addition to all their commitment to energy savings and efficiency, they are equally consistent in working on their production-side sustainability. From starting with 100% virgin raw material at startup time, they are now at nearly 100% recycled and compostable material.

When asked about concrete visions or dreams for the near future, the answer is rather down-to-earth: „Two days away from the company, but everything continues to run“ – that’s a good vision. But of course they are well aware of the challenges ahead and want to face them. And who knows, „maybe we’ll become the smallest smart factory in Europe.“

Info box

Production profile of Emperor Mouldings:

- All Zeres machines run smoothly in 24/6mode;

- All machines are equipped with automation;

- During the day, the machines are serviced and processes optimized if necessary; at night, they produce unmanned;

- Only small parts with a high number of pieces are produced.