With its upgraded top sellers Mars and Jupiter Series, Haitian International is sending two clear signals at the K-Show in challenging times: Continuity and reliability.

Haitian International’s current machine portfolio serves almost all requirements in plastics processing – and new performance advantages and further industry-specific series versions are being added all the time. The latest example is the high-speed packaging version of the worldwide bestseller: the Haitian Mars K Series, with an innovative injection unit (integrated direct pressure accumulator), injection rates of up to 1000 mm/s and other innovations. This packaging solution of Mars Series will celebrate its European premiere in Düsseldorf.

The proven two-platen solution of the Haitian Jupiter Series, available with up to 66,000 kN of power, is also undergoing continuous development. For example, with new wide-platen versions for even more free space or with even more energy-efficient servo drives in the form of the latest generation of motors from Haitian Drive Systems.

The exhibits in Hall 15, Booth A57

Standardized interfaces and open system integration guarantee processors maximum possibilities in terms of connectivity and absolute freedom in the choice of their automation or MES partners.

All Haitian exhibits at K-Show 2022 will be live networked with 2 MES systems. One of these is the MES system from Icon S.r.l., Italy – Haitian International Germany’s new cooperation partner for the European market. The free process monitoring system “Go Factory 2.0” from Haitian Smart Solutions will also be presented, available for the Chinese Market so far.

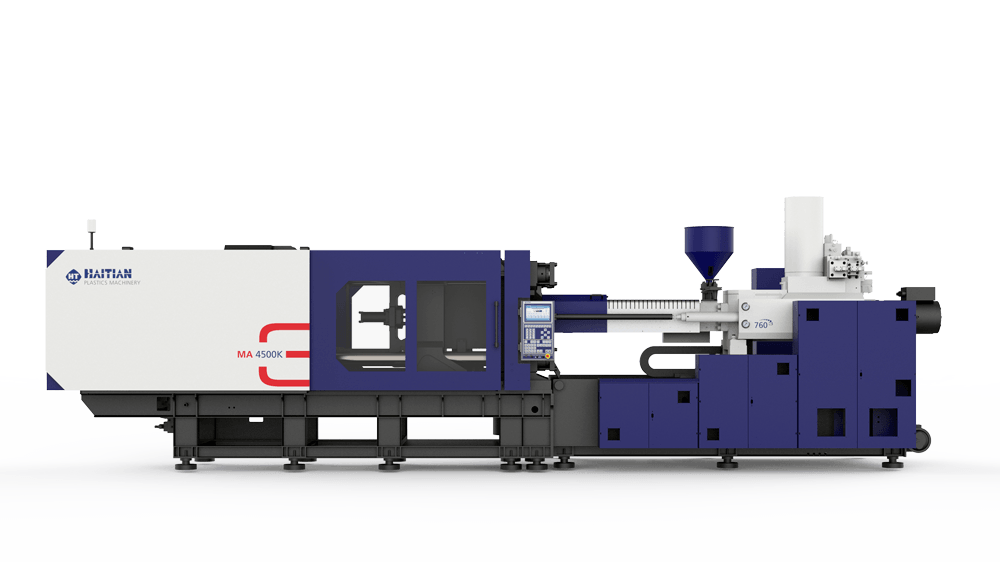

Haitian Mars K Series – European premiere with high speed

The K version of the energy-efficient bestseller can be experienced live in Europe for the first time as a high-speed solution for packaging and thin-walled parts.

Highlights:

-

Fast injection speed up to 1000 mm/s

-

Customized high-performance servo drive guarantees fastest response times

-

Injection unit with integrated direct pressure accumulator

-

Electric dosing aiming for efficiency and short cycles

-

Super-conductive quartz heating system for precise temperature control with low energy consumption

-

High plasticizing performance

-

Dedicated V-toggle design stabilizes molds, e.g. with high cavities, and significantly improves life time of parts

Live application of Mars K:

An MA4500K produces a 25 g food container including lid. Parts are produced with in-mold labeling technology. Unloading is done with a Hilectro linear robot from Haitian Smart Solutions.

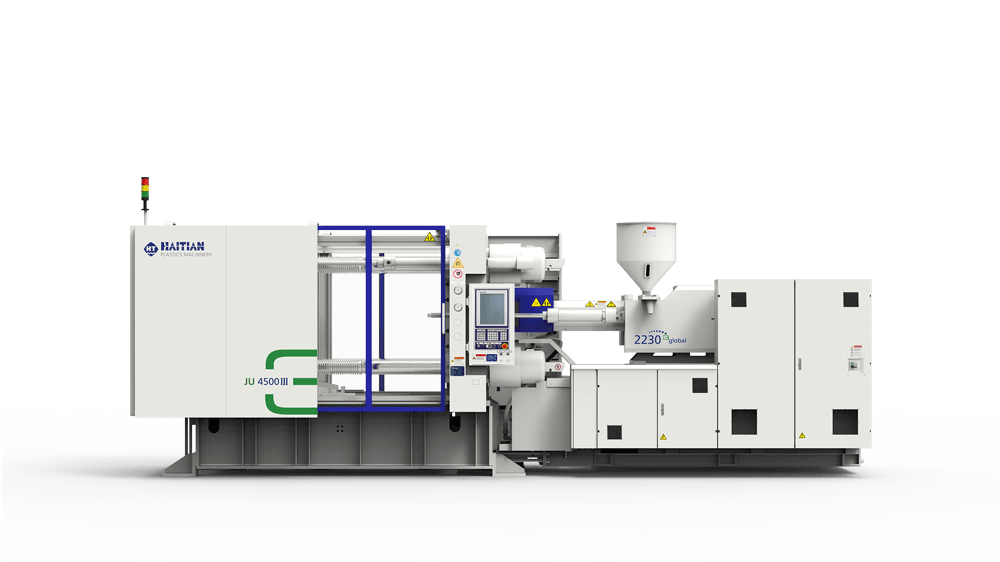

Haitian Jupiter Series – established two-platen technology

The space-saving two-platen Haitian Jupiter Series solution, available with clamping forces from 4,500 kN to 66,000 kN, with focus on the automotive and logistics industries. In response to increasing demand, wide-platen versions are now also available for even more free space in the mold room. All Jupiters offer energy-efficient servo hydraulics with the latest generation of motors from Haitian Drive Systems.

Live application of the Jupiter:

A JU4500 produces an avocado transport box with 480 g part weight from regranulated HDPE mixed with a “Tetrapak” recyclate. The mold is equipped with a high-precision, electric and oil-free cascade control system from HRS.

We would like to thank our long-term partners Maas (conveyor), Piovan (material handling) for their support. The gripper for part removal is provided by AGS (Automation Greifsysteme Schwope GmbH)

The box is taken from a Hilectro V1300ID – X4000 with extended x-axis, drop behind the machine.

Haitian Mars K Series –

Highspeed solution for packaging and thin-walled parts

Haitian Jupiter III Series –

Space saving two-platen technology