Haitian Precision at EMO 2025 in Hannover

At EMO 2025, Haitian will present its expanded portfolio of high-speed and high-precision machining solutions. With a clear focus on vertical, horizontal, and CNC turning/milling centers, the machines are designed for maximum productivity and highest accuracy.

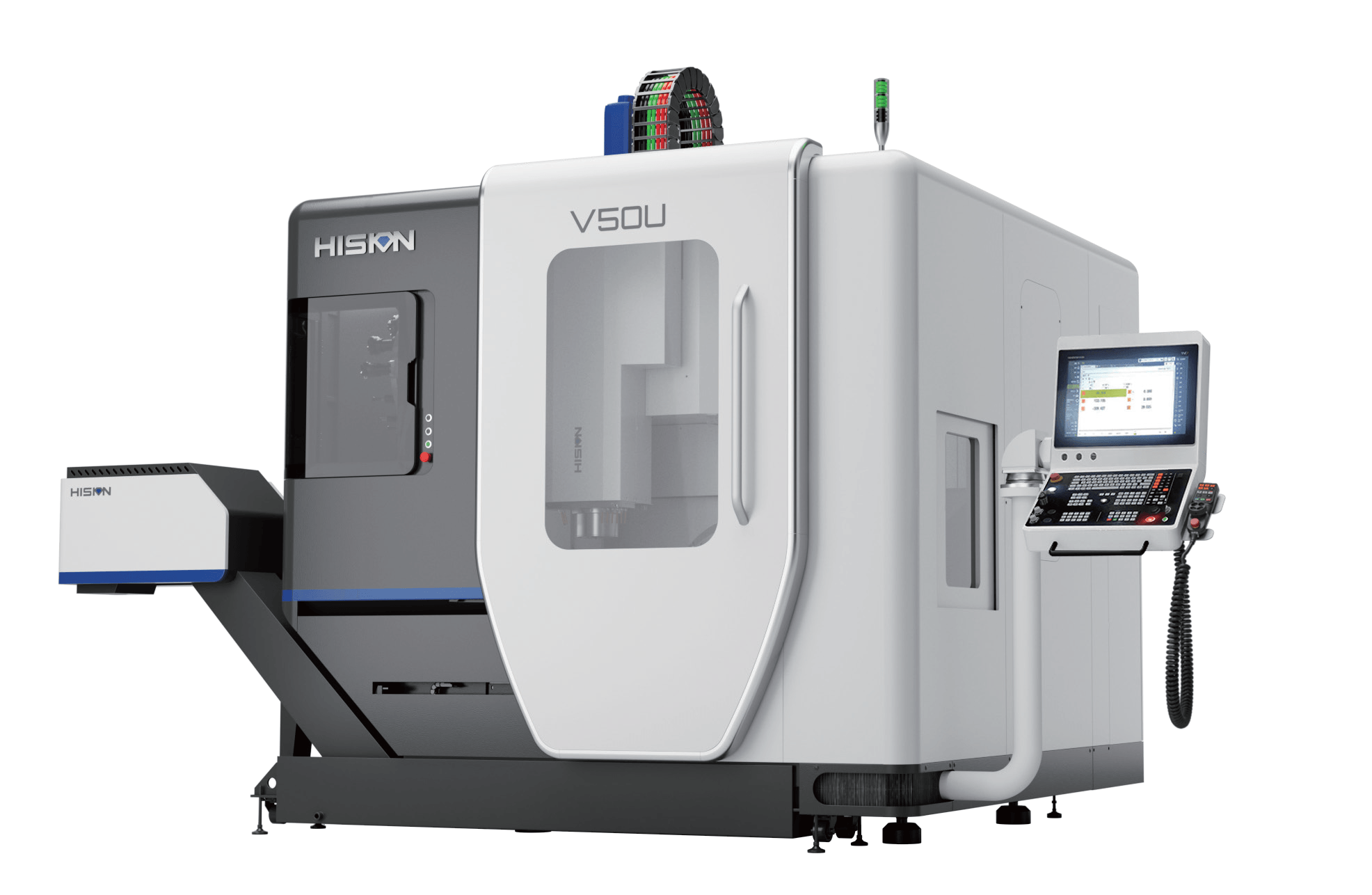

V50U – Premium 5-Axis Vertical Machining Center

The V50U is a newly developed 5-axis high-speed machining center designed for simultaneous machining of complex precision components.

Featuring optimized dynamic rigidity and the latest Heidenhain TNC7 control, the V50U enables 5-sided machining in a single setup. This significantly reduces repositioning times while increasing both efficiency and precision. With travels of 650 x 520 x 475 mm and a spindle speed of 15,000 rpm, the V50U is ideally suited for highly dynamic 5-axis machining.

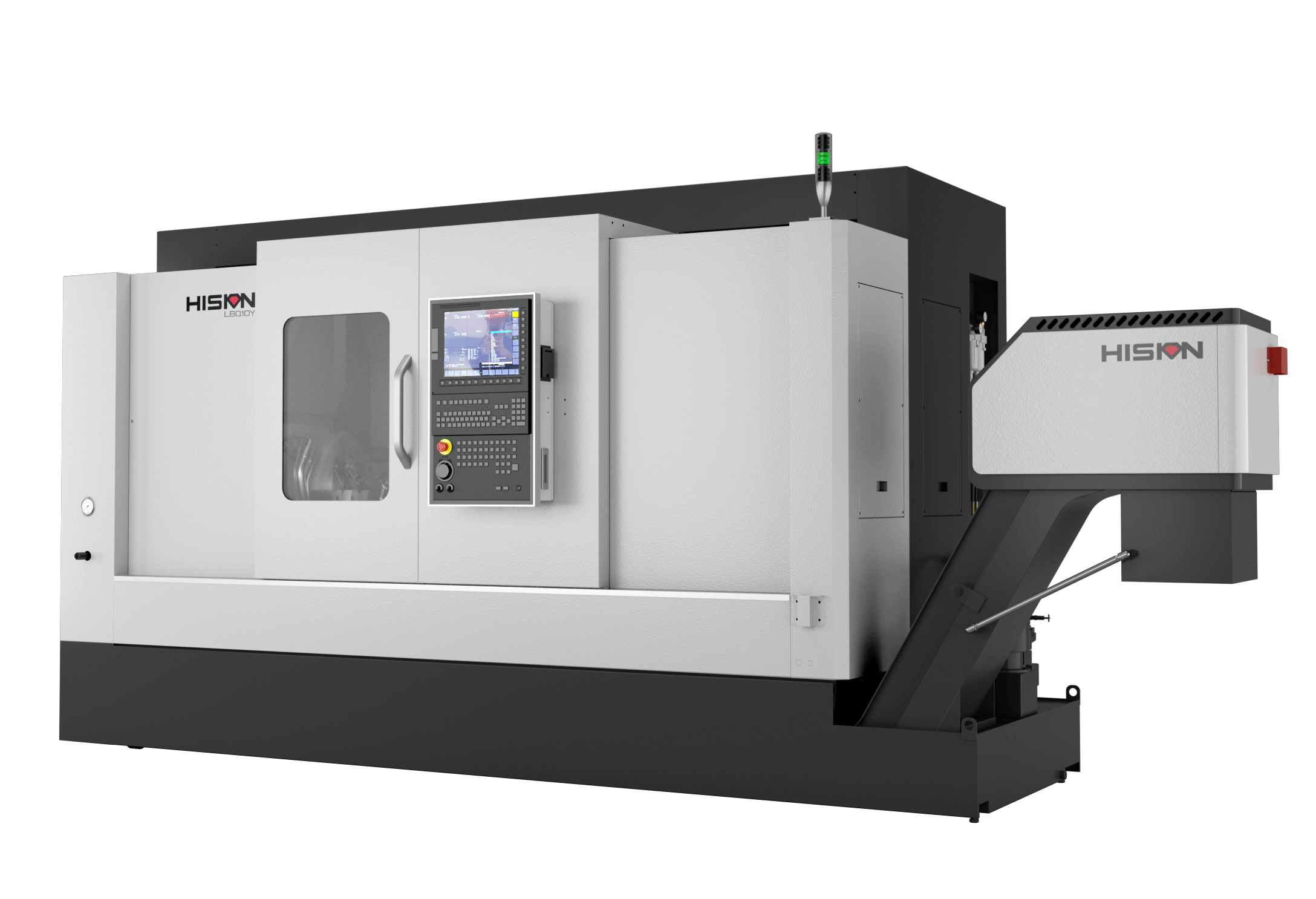

LBQ10Y – CNC Turning and Milling Center

The LBQ10Y combines powerful turning capabilities with extensive milling functions in a single machine. Its robust box-way construction provides high rigidity and excellent vibration damping, even during demanding machining tasks.

Equipped with a Y-axis and interpolation functionality, the LBQ10Y enables precise complete machining of workpieces in one setup. Compatibility with 10–15 inch chucks expands the range of applications and increases manufacturing flexibility.

Direct drives, automatic tool changer and advanced control features ensure short non-cutting times and maximum process reliability. The LBQ10Y offers a perfect balance of performance, precision, and productivity.

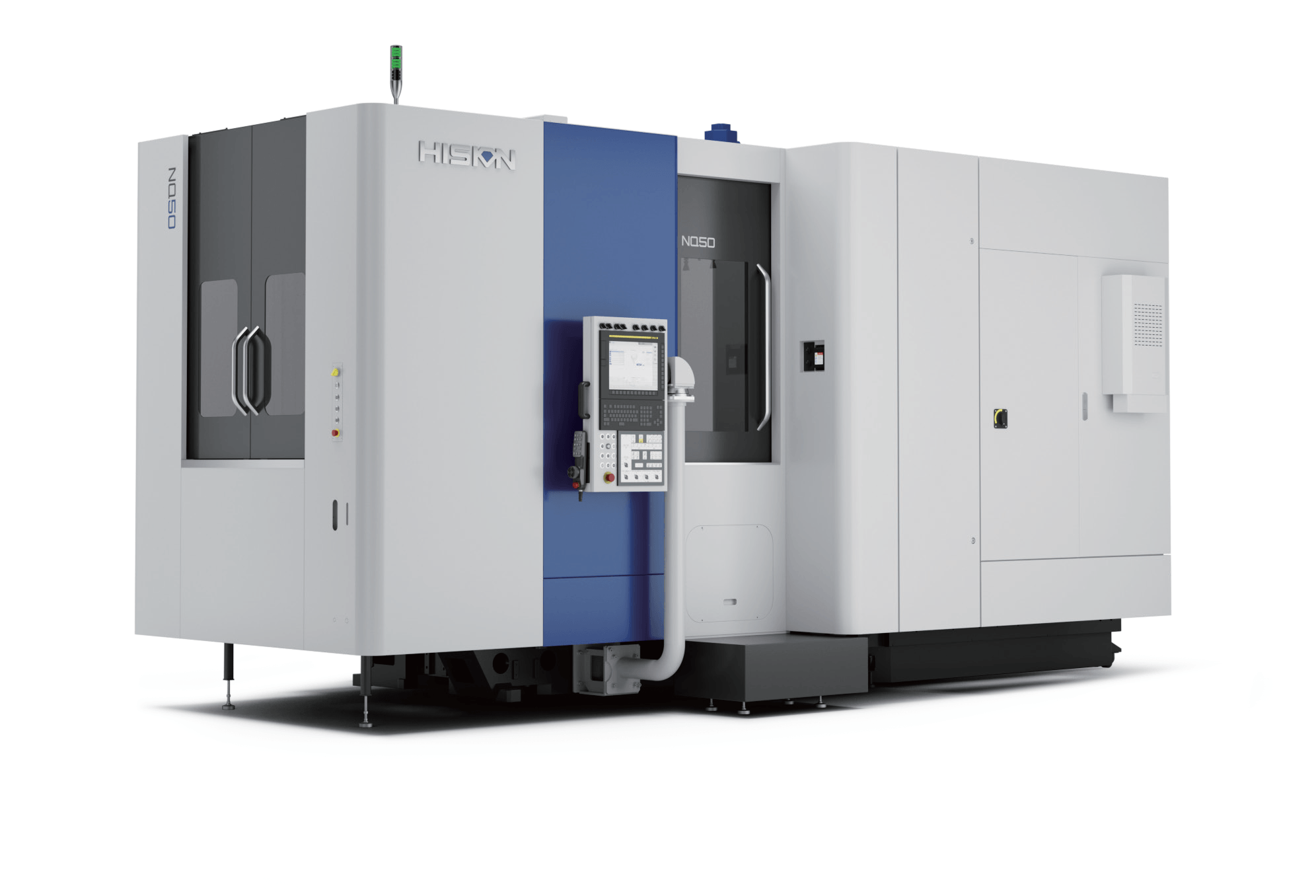

NQ50 – Horizontal Machining Center

The NQ50 was developed for high-precision, high-efficiency series production. With a stable machine construction, wide guideways, and a powerful spindle drive, it delivers top accuracy and process stability even during long machining cycles.

Its modular design allows easy integration into automated production lines, while standardized interfaces provide flexible adaptation to various production requirements.

Additionally, direct-drive axes, advanced thermal compensation, and an integrated tool and pallet changer contribute to short idle times and consistently high machining quality. The NQ50 combines speed, precision, and cost-effectiveness in a compact and future-proof design.

Visit at Hall 16 | Booth D14

Media Contact Europe

Dominik Wiesner

Marketing & Communications Europe