Ritter GmbH is an established plastics processor in Europe, specialized in complete solutions for various industries. The company supplies cartridges for sealants and adhesives, high-precision products for clinical and laboratory applications, as well as lawn honeycombs and other fasteners for green and traffic areas to customers all over the world. The corona pandemic has changed a lot in the industry. The team in the family-owned company Ritter GmbH act flexibly and look to the future without fear.

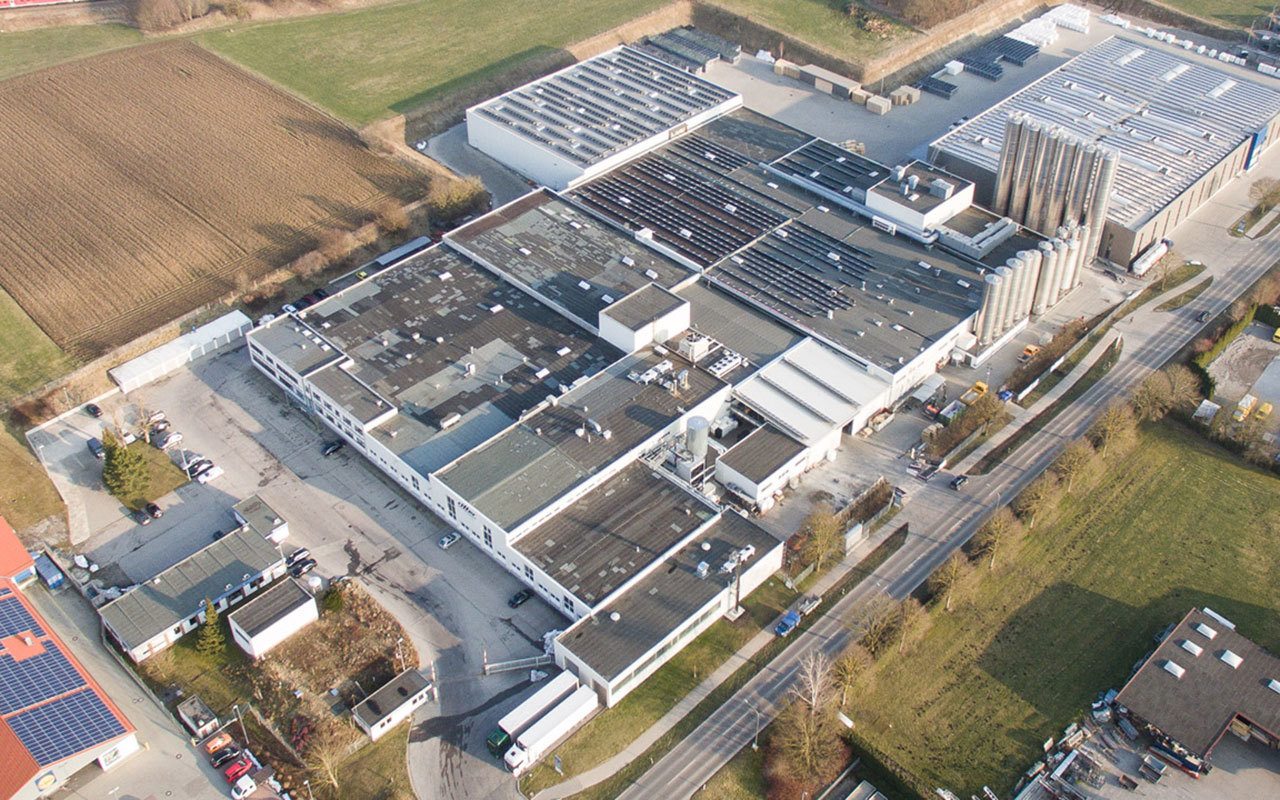

Company headquarters in Schwabmüchen with over 30,000 sqm

“Shock was not an option”

These are special times when we visit Ritter in Schwabmünchen, Bavaria. Managing Director Frank Ritter opens our talk with a review of March 2020: “We were in the final stages of building the new production hall when the government initiated the lockdown. The epidemiological developments in China did not bode well even before that. But shock was not an option, we had to take action. So we reacted quickly. Emergency plans as well as hygiene measures were initiated, new shifts were assigned, the transition to the home office, and much more. All employees were involved and were highly cooperative. All this took on a group dynamic that made me really proud as an entrepreneur.

Frank Ritter, managing director of Ritter GmbH, in front of a full distribution center. Every year, over 9000 truckloads leave the factory

“We suddenly became system-relevant”

The company had just completed the new building in February, so that the infrastructure was ready for expansion. Within a few weeks, production was ramped up. When the pandemic reached Germany, it was high time to act. Injection molding companies in the medical sector suddenly became system-relevant – virtually overnight. “We had molds in stock or were able to build them ourselves quickly,” Ritter recalls, “but the right machines were missing. For this we needed partners who could deliver very fast. Haitian International Germany was able to act immediately, which gave us a great advantage.”

In the medical sector, Ritter relies without exception on electrical machines, and the electrical series from Zhafir had already proven their worth in the Slovenian plant. “Zhafir machines are more economical in energy consumption, quieter, cleaner and have lower maintenance costs in the long term,” enthuses Ritter and is pleased with the Zeres Series with integrated hydraulics. “Zhafir is definitely in a different price league, which gives us enormous room for maneuver and makes the ROI more accessible. “Technology to the Point” is really the order of the day. Of the initial ten new Zeres, seven units were “married to robots” and used in the gray room, screw caps for cartridges are running on three more Zeres-F (fast injection, short cycles); further Zeres machines are to follow, even if the team had to “warm up” with the new ones first.

Full of ideas even in times of crisis

As far as the current order situation is concerned, Ritter is on the one hand very satisfied, but nevertheless concerned. Although Ritter, like many other companies, had initially announced short-time work for safety reasons, the situation was suddenly reversed.

“Our order books were more than full overnight. We had been working at full speed, up to the limit, for months. But it’s not enough, we need more manpower,” explains Ritter. Although the 365-strong workforce has now been increased by around 90 employees, the company is still looking for around 100 new employees by mid 2021. Here too, Ritter shows himself to be imaginative and flexible: “Of course we want to support Germany and Europe, of course we see it as our duty. But we can’t do it on our own, we can only do it together with other companies”.

The managing directors of Ritter would have preferred a model of solidarity with other companies in the region, “a kind of employment pact. In this way, for example, employees from companies that are currently on short-time work could have temporarily supported our team. However, this could not be implemented because employees from other companies were covered by the short-time work allowance. Therefore, we had to recruit our own employees as quickly as possible.

On a Zhafir Zeres-F Series with 300 Tons clamping force: Production of a piston for one cartridge

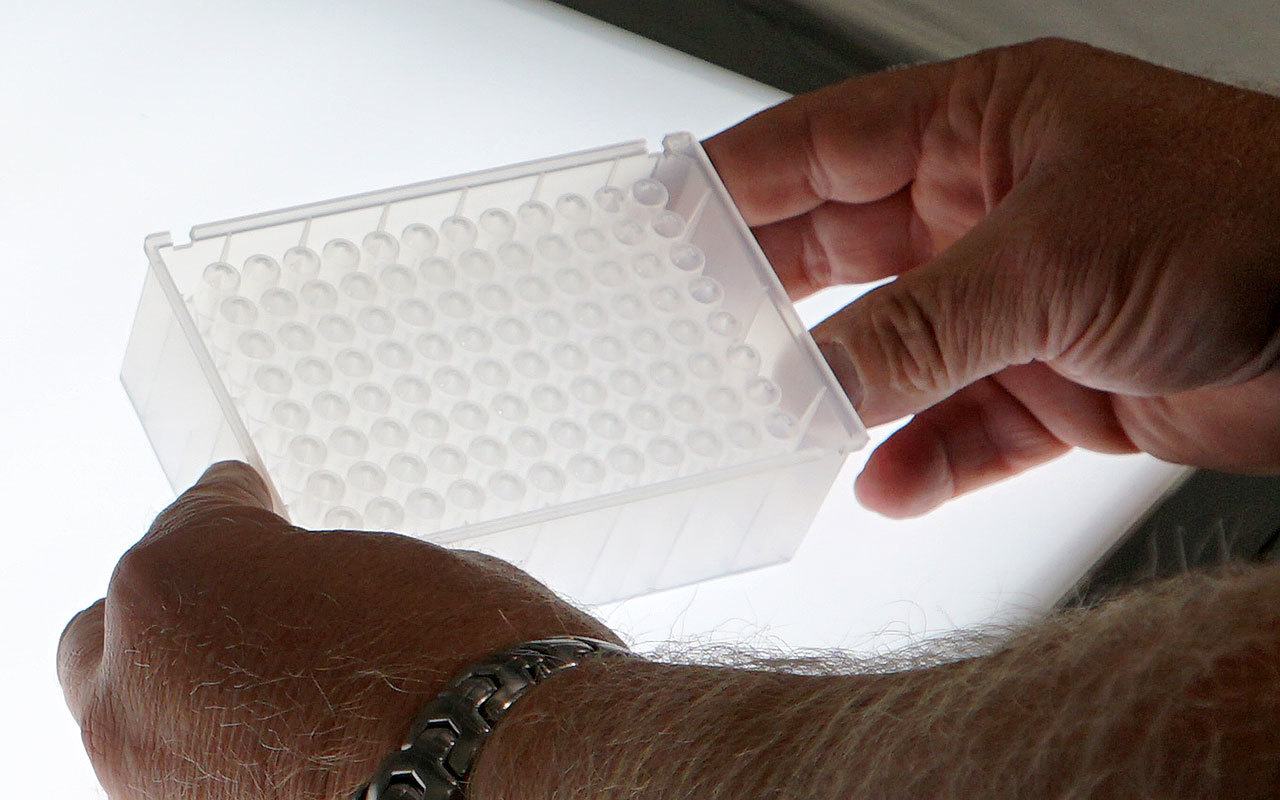

On a Zhafir Zeres Series with 120 Tons clamping force: Production of Riplate® Microtiter plates for laboratories

“We’ve never had a service like this before”

“It would be nonsense to claim that a completely new series means no start-up difficulties for the machine operators. But Haitian once again reacted quickly and organized a training course for us in Schwabmünchen. And it was completely free of charge.” The initial skepticism could be cleared up and uncertainties could be resolved directly. “We have never had such a service before,” Ritter sums up. “Since then, the machines have been running over 700 hours a month. With the usual minor details as with any of our other machines as well”. Due to the gigantic demand for medical products and the classification as a system-relevant company, the Zeres run in 24/7 mode.

Keyword Environment & Resources

One of Ritter’s core objectives is sustainable production efficiency through high vertical integration and series production to perfection. “We can map the entire process, which makes us independent and extremely flexible,” says Ritter. True to this philosophy, the expansive construction projects are also characterized by independence and combine cost efficiency with sustainability in an exemplary manner.

Take the example of recycling management: recycled materials are mainly used for building material products, while landscaping uses only recycled products, and has been for a long time.

Keyword environment & resources: On sunny days the ISO-50001-certified company is almost self-sufficient. The roof areas of the parking lots are used for the company’s own power generation with a total of 1250 kWp photovoltaic systems. 3 block-type thermal power stations generate two thirds of the power requirement, whose waste heat is also used highly efficiently for cooling; a fully automatic energy management system (heat, cold, light, air conditioning) ensures maximum savings in the new building and energy-efficient machines form the heart of the whole. Only tested and pollutant-free plastics are used in production, which can be recycled.

In addition, Ritter uses biodegradable or compostable raw materials and tests various materials – of course with a view to the future. “In the medical sector, the use of recycled materials is unthinkable; only certified materials are permitted here. But in non-food packaging we are experiencing a structural change, more and more projects with new recycled materials are coming up on the table”.

Two brothers on big tracks

In 2002, Ralf and Frank Ritter took over Ritter GmbH, founded in 1965, from their parents. With multi-part cartridge systems, high-precision medical products and robust floor honeycombs made of recycled materials, the company is broadly positioned. The high-quality product portfolio is based on numerous patents.